How To Engrave Leather: Top 7 Engraving Methods Explained

In the annals of history, leather has served as a canvas for human expression. It was the Greeks who pioneered the art of engraving leather, embellishing it with distinctive symbols and patterns. As time progressed, leather became the medium for preserving sacred manuscripts. The earliest engravings were crafted using stones and other sharp materials, showcasing the hand artistry of the time.

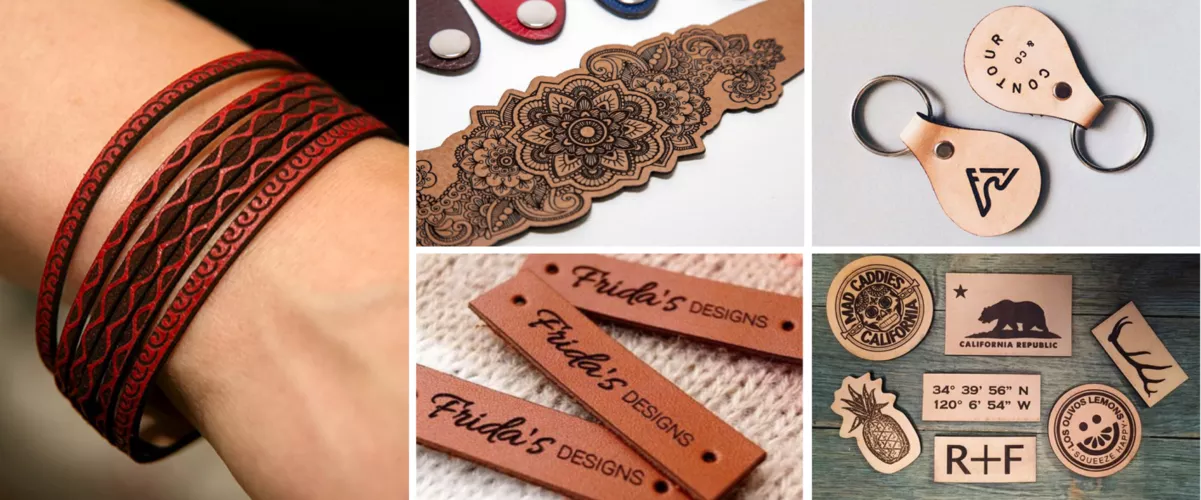

Multiple leather engraving methods have evolved over the years, thanks to tech advancements. This article aims to highlight the top 7 leather engraving techniques, discussing in detail the tools they use and the industries they cater to.

In This Article

- Method 1: Engraving Leather by Hand

- Method 2: Laser Engraving Leather

- Method 3: Leather Embossing And Debossing

- Method 4: Hot Stamping Leather

- Method 5: Leather Pyrography

- Method 6: Leather Embroidery

- Method 7: Perforation

- FAQs of Leather Engraving

Method 1: Engraving Leather by Hand

Hand leather engraving is a generalized term for carving. It is an art form that transforms leather into a canvas of intricate designs and patterns. It adds a personal touch; each stroke reflects the artisan's skill and creativity.

In this process, designs are imprinted onto dampened leather with specialized tools. The hand carving results in raised and recessed areas that create a multi-dimensional effect.

Tools Used for Leather Carving

Artisans use a variety of tools based on their skill and experience. However, some essential tools that every beginner or seasoned professional needs are:

- Swivel Knife: This is the primary tool for carving. It has a yoke-shaped handle with a flexible, rotating blade, which allows for smooth, curved cuts.

- Beveler: Essential for giving depth to the cuts, a beveler creates a three-dimensional look by pushing down the leather around the cuts. It is usually hammered by a mallet.

- Background Tools: These tools, including the matte backgrounder, are used to create textured or patterned backgrounds. They add depth and contrast to the main design.

- Pear Shader: It is employed to create rounded impressions or depressions, which add contour and depth to the design.

- Mallet or Maul: A weighted tool used to strike other tools; it ensures even pressure and depth.

Steps for Carving Leather

Before we move on to the steps, you need to remember that leather carving is a process that requires patience and precision. Each step is crucial, and attention to detail makes all the difference in the final outcome.

- Trace the Design: Place your chosen design beneath the wax paper. Carefully trace over it, and make sure all details are captured. Printed designs often make this process easier.

- Dampen the Leather: Use a sponge or water spray to moisten the leather. The leather has to be wet but not dripping. As it darkens, wait for it to lighten slightly.

- Transfer the Pattern: Position the traced wax paper over the leather. With a pencil, gently trace the design onto the leather. The design needs to be visible but not but not too deep.

- Cutting the Lines: Holding the swivel knife comfortably, trace over the design on the leather. The cuts should be consistent but not too deep. As a rule of thumb, the depth needs to be half the thickness of the material.

- Tooling with Bevel Stamp: Outline your shapes with the bevel stamp, giving them a pronounced, raised appearance. This step adds dimension to the carving.

- Background Tooling: Use background tools, especially the matte backgrounder, to create textured or patterned backgrounds. This step enhances the main design's prominence and adds depth.

- Tooling with Pear Shader: Position the pear shader on areas like the insides of leaves or petals. Gently tap with the mallet to create rounded impressions. This further adds depth and contour to the design.

- Additional Tooling: Explore with other stamps, like the camouflage, Weiner, and weaving stamps, to infuse more intricate details into your design.

- Drying and Finishing: After the leather is dry, you may apply a coat of Neats oil, and spray a quick shine spray onto it. Let it settle. Then, apply an antique finish paste that settles in leather pores. Wipe it, the higher parts will get cleaned while the lower parts will catch antiques. This will create a two-tone leather.

©Springfield Leather – YouTube

Method 2: Laser Engraving Leather

Laser engraving is a modern method for imprinting designs onto the leather. In this process, a concentrated beam of light interacts with the material’s surface. The intense beam vaporizes the leather in a controlled manner. This results in clean, detailed, and permanent designs on the leather. The depth, darkness, and texture of the engraving can be adjusted based on the laser’s power and speed settings.

The standout feature of laser engraving is its precision. It can reproduce intricate patterns, texts, and images with a level of detail that’s hard to achieve with manual methods. Moreover, since no physical tool or touch is involved, there is minimal wear on the leather and consistent results across large batches.

Laser engraving is great for small businesses or for designing leather crafts at home. Whether it’s creating a personal name tag wallet or key chain, laser engraving comes to the rescue.

Tools Needed for Laser Engraving Leather

Primarily, you need these three things for laser engraving leather:

- Laser Engraving Design: This is the digital blueprint of the design you intend to engrave. It guides the laser machine on where and how to burn the leather. You may download it for free or create your own on a Laser Design software.

- Design Software: Programs like Adobe Illustrator, or specialized laser software (LightBurn, XCS) are used to create and modify laser engraving designs. They allow users to adjust design parameters before engraving to obtain optimum results.

- Laser Engraving Machine: The core tool responsible for the engraving process. It houses the laser and interprets the laser engraving file to engrave the design onto the leather. A powerful CO2 laser machine, such as xTool P2, or smart diode laser machines like xTool M1 are the perfect options to use.

Laser Engraving Leather Procedure

Multiple laser engraving machines are available in the market. The engraving process is mostly similar, however, quality and results may differ. Here’s how you can laser engrave leather with xTool M1:

- Design Creation: Start by creating or choosing a design. Use design software to either craft a new design or modify an existing one to fit your requirements. Or you may download it for free from the Internet. Load the file into the laser software.

- Machine Setup: Put the leather piece into the machine. Click the distance measurement icon in the software to focus the laser head. Then drag the design onto the leather with the help of the preview.

- Adjust Engraving Settings: xTool provides preset parameters for different materials in the software. Just select your material to get the settings. You can also manually adjust them.

- Engraving: Start the engraving process, allowing the machine to engrave the design onto the leather.

- Post-Engraving Cleanup: After engraving, there might be some residue or soot marks on the leather. One of the techniques is applying painter’s tape to the engraved leather. Press it hard and repeat the procedure until you have a clean and pristine leather.

©Cole Minor Kustoms – Youtube

Method 3: Leather Embossing And Debossing

Leather embossing and debossing are techniques used to create raised or recessed relief designs on leather by pressing it with stamps. Although both methods involve applying pressure to the leather to alter its surface, they achieve opposite effects.

Embossing raises the leather's surface by creating a three-dimensional or raised design. On the contrary, debossing pushes the leather down, creating an indented or recessed design.

Tools Used for Leather Embossing

- Dies or Stamps: These are metal plates or tools with the desired design. They can be crafted with CNC machines, carrying the negative image of your branding or mark.

- Armor Press or Mallet: Used to apply pressure, which forces the leather to take on the shape of a stamp.

How to Emboss a Stamp on Leather?

Here’s a short procedure to emboss a maker’s mark stamp on a leather piece:

- Get a Stamp to Emboss: Get or create a stamp to emboss on leather. It may be some ready-made stamps, ones available in the market, or your personal maker’s mark stamp.

- Leather Casing: Dampen a soft cloth or sponge with water and evenly wet the leather surface. This process, known as casing, relaxes the leather fiber. As a result, the embossed design is crisp and clear.

- Position the Stamp: Place the prepared stamp over the damp leather; align it precisely where you want the design to be embossed.

- Place on Armor Press: Position the leather with the stamp on the armor press. Again, ensure everything is aligned correctly.

- Apply Pressure: Using the armor press, apply even pressure to the stamp. This causes the design to be imprinted onto the leather. The dampness of the leather will aid in a clear and defined embossing.

- Remove and Dry: After embossing, remove the leather from the press and let it dry naturally. As it dries, the embossed design will set and give a permanent elevated pattern.

©GeordieLeather

Method 4: Hot Stamping Leather - Branding and Foiling

Hot stamping is a specialized form of leather embossing technique where a heated stamp is pressed into the leather. This method has further two variations: branding and foiling.

Leather Branding is similar to livestock branding, where animals are marked with a hot stamp. It is a process in which a hot stamp (via heat imprinter) is used to imprint a design on the leather. The hot stamp burns the hide and creates a sunken design with a unique texture and color.

Foiling introduces color to the mix. It is similar to branding but uses colored foils. In the foil stamping process, we place a tinted foil in between the stamp and the leather. Then, apply heat and pressure through a heat imprinter. The colored pattern gets embossed on the leather.

Tools Used for Hot Stamping Leather

- Heat Imprinter: It is a specialized electrical device that heats the stamp to the required temperature for effective stamping. You can place any customized stamps on it and change the temperature to any required value.

- Stamp: It can be custom-made or simple letter stamps, which are to be engraved into the leather.

- Tinted Foil: They are colored sheets, used in the foiling process to transfer color onto the leather.

How to Hot Stamp Leather?

The hot stamping process is carried out with a heat imprinter. Here’s how you can do it if you’ve access to that tool:

- Preparation: Clean the leather surface to ensure no dirt or oils interfere with the stamping.

- Get a Stamp: You need a stamp to place inside the hot imprinter. It can be ready-made letters or your brand stamp.

- Heat the Stamp: Place the stamp in the heat imprinter and set a temperature. You can set it in the range of 100 -130 degrees Celsius. The more the temperature, the more burnt results will be.

- Position the Stamp: Align the heated stamp on the area of the leather where you want the design.

- For Foiling: Place the tinted foil between the leather and the heated stamp. Press down firmly just for a couple of seconds. Make sure the heat and pressure transfer the foil’s color onto the leather.

- For Branding: Press the heated stamp directly onto the leather without the tainted sheet. Remember seconds of hold will produce a clear imprint on the leather.

- Cool Down: After stamping, allow the leather to cool naturally. This sets the design, whether it’s a simple imprint or a colored foil design.

©Whit+Park – Youtube

Method 5: Leather Pyrography

The term “pyrography” comes from the Greek words “pur” (fire) and “graphos” (writing). It literally translates to “writing with fire.” The heat from the tool burns into the material and creates intricate designs.

Wood is the most common substrate for pyrography. However, the technique can also be applied to other materials, including leather, paper, and gourds. The varying temperatures of the tool and the duration of its application determine the depth and shade of the burn. This allows artists to achieve a range of tones and depths.

Remember that pyrography should only be done on vegetable-tanned leather as it is safe for burning. This leather is tanned with organic non-toxic substances, so it doesn’t release those poisonous fumes.

Tools Used for Leather Pyrography

- Pyrography burner with appropriate nibs: It’s an electric device that heats up specialized tips (nibs) to burn designs onto the leather. Different nibs can be attached to achieve various effects and line thicknesses.

- Carbon paper: A special paper used to transfer the pattern design onto the leather. One side of the paper is coated with a dark pigment (usually carbon), which transfers onto the leather when pressure is applied.

- Leather conditioner: A product applied to the leather after pyrography. It helps to protect, moisturize, and enhance the appearance of the leather, giving it a finished look.

How to Do Pyrography on Leather?

It is a simple technique, however, you’ve to be careful while following these steps if you want to achieve perfect results:

- Preparation: Oils or moisture from your hands can stain the leather. So, before you begin the process, make sure your hands are clean and dry. Use a piece of paper as a barrier between your hand and the leather to prevent any oil transfer.

- Leather Wetting: Wet the leather on both sides using a damp washcloth to make it firmer. Let it sit for 24 hours on a flat surface to prevent curling.

- Pattern Transfer: Take a suitable piece of leather, probably larger than your pattern. Cut out the unnecessary parts of the pattern and align it on the leather. Tape the pattern from the top and place carbon paper (shiny side down) between the pattern and the leather.

- Pyrography Process: Choose the appropriate nib for your burner. A cone tip would be fine. Test the burner on the practice leather piece to get a feel for the heat and motion.

- Post Pyrography: Once the pyrography is complete, apply the leather conditioner with a rag to protect and enhance the leather.

©Burn Savy – YouTube

Carefully trace over the pattern using the transfer tool. Check periodically to ensure the pattern is transferring correctly.

Always keep the burner in motion to avoid blobby lines. Trace over the entire pattern on your main leather piece.

Method 6: Leather Embroidery

Leather embroidery is the art of stitching designs onto leather surfaces using threads. Unlike fabric embroidery, leather embroidery requires specialized techniques and tools due to the leather’s thickness and rigidity.

Embroidering on leather is a delicate process that can be done manually or through an advanced embroidery machine. The design is first mapped out and then stitched onto the leather. This technique is mainly used for creating and styling leather clothing items.

Tools Used for Leather Embroidery

- Embroidery Machine: For large-scale or commercial projects, an embroidery machine that can handle leather is essential.

- Embroidery Needles: They are specialized needles, usually thicker and stronger than regular embroidery needles. They penetrate the leather without breaking.

- Embroidery Thread: Polyester or rayon threads are commonly used for leather embroidery.

- Leather Punch or Awl: Used to pre-punch holes in the leather, making it easier to pass the needle through.

- Embroidery Hoop: Holds the leather taut during the embroidery process.

- Stabilizer: A white color paper or fabric stabilizer is placed behind the leather to provide support during the embroidery process.

How to do Hand Embroidery on Leather?

- Sketch or trace the design onto the leather using a pencil.

- Use the leather punch or awl to pre-punch holes following the design.

- Choose your embroidery thread and thread the needle. Start embroidery by passing thread through the pre-punched holes, following the design.

- Once the design is complete, knot the thread on the backside of the leather to secure it. Trim any excess thread.

©Durong Lam – YouTube

Machine Embroidery Method

- Clean the leather surface to remove any oils or residues. Position a stabilizer behind the leather to provide support during embroidery.

- Select or create a design you want to transfer onto leather. Feed this design to the leather embroidery machine.

- Start the embroidery process by creating an outline of the design. Then, allow the machine to stitch the design onto the leather.

- Once the embroidery is complete, remove any excess stabilizer and clean up stray threads.

©CoL Desi Inc – Youtube

Method 7: Perforation

It is an extension of leather embroidery. Perforation refers to the process of creating a series of small holes in a material, in this context, leather. These holes can be for functional purposes, such as allowing ventilation, or for decorative reasons. Perforated leather is commonly seen in car interiors, footwear, and fashion accessories, like belts and watch bands.

Perforation is achieved by pressing sharp tools through the leather in a patterned or random manner. The size, spacing, and pattern of the holes can vary based on the desired outcome. It can be performed manually, however, most projects require the need for dedicated perforation machines.

Tools Needed

This method ideally requires just a perforation machine. It is mostly a CNC machine, to create holes in selected design areas. It comes equipped with a series of needles or punches that create those holes.

Perforation Process

RichPeace CNC Leather Perforation Machine

Clean the leather surface to ensure it is free from dirt or oils. Then, set up the CNC machine, and select hole size, spacing, and pattern. Load the leather onto the machine’s conveyor and initiate the process.

FAQs of Leather Engraving

What Is The Easiest Way To Engrave Leather?

When considering the ease of engraving, especially for beginners, the key factors are the simplicity of the process and minimal manual intervention. You need to consider: can someone without prior experience or hand skills dive right in? Ideally, the method should be automated and require few, if any, manual tools.

Given these criteria, laser engraving emerges as the top choice. Devices like the xTool S1 or the compact M1 make the process almost effortless. With just a click of a button, these machines can precisely engrave leather items. The best part is there’s no need for any prior experience, hand tools, or specialized skills.

What Can You Use to Engrave Leather?

You have several options to engrave leather. Traditional methods include using hand tools and stamps. While speaking of tech options, you have a laser machine to engrave anything on leather. Additionally, there are specific pens designed to burn designs into leather, offering another method for engraving.

Can You Engrave Leather at Home?

Most of the engraving methods discussed can be performed from the comfort of your home, provided you have the tools. For instance, if you’re interested in carving, all you will need is a swivel knife. Embossing can be achieved with a simple stamp. And for those looking for a tech-savvy approach, compact laser engraving machines like the xTool M1 can make home leather engraving a breeze.

What is the Best Engraving Tool for Leather?

The “best” tool depends on the individual's experience and preference. For those who appreciate the artistry of manual work, carving with a swivel knife can be a fulfilling hobby. However, for beginners, a laser engraving machine is both ideal and arguably the easiest approach.

Can You Engrave Leather with a Dremel?

Yes, a Dremel tool can be used to engrave leather. It comes with various attachments and adjustable speed settings, which make it a handy tool for creating designs on leather. However, it requires a steady hand and some practice to achieve precise results.

How Do You Put Words on Leather?

Words can be imprinted on leather through methods like hot stamping, where heated metal stamps are pressed onto the leather to leave an impression. Another efficient method is laser engraving, which can accurately etch words onto leather with precision and clarity.

Conclusion

Leather, with its rich history and timeless appeal, continues to captivate artisans and consumers alike. The multiple techniques available today, from hand carving to advanced laser engraving, showcase the versatility of this cherished material.

Each method, whether traditional or modern, brings its own charm and uniqueness to the finished product. As technology advances, so do the possibilities for leatherwork. Thanks to laser engraving, now you can safely perform leather engraving from the comfort of your home!