Each year, the customized and DIY jewelry trends continue to evolve. DIY jewelry has huge demand and captivates fashion enthusiasts worldwide. The introduction of laser-cut jewelry is a huge milestone, keeping in view the DIY trend.

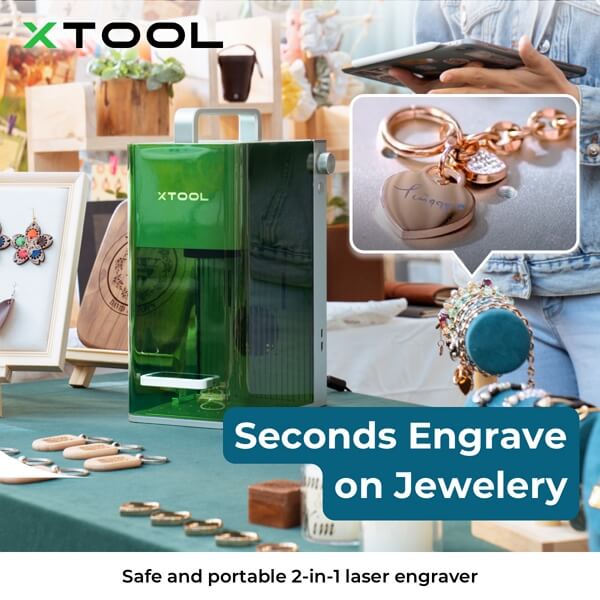

Considering the increased demand for DIY jewelry, many entrepreneurs have launched small businesses. These small business owners sell personalized jewelry using laser cutting technology.

For some, laser-cut jewelry is a business, and for some, it's a hobby. This blog explains the potential success of laser-cut jewelry in the market. It also includes a comprehensive step-by-step guide on making laser-cut jewelry using a laser cutter.

In This Article

- The Potential of Laser-Cut Jewelry

- Step1: Designing Your Laser-Cut Jewelry

- Step 2: Selecting Materials

- Step 4: Production Process

- Step 5: Post-Creation Processes

- Conclusion

The Potential of Laser-Cut Jewelry

Gone are the days when precious gems, solitaires, and gold were considered the only luxury form of jewelry. Today, the mindset has changed. Personalization has taken the consumer market by storm. If you want to take advantage of this trend, investing your creativity in laser-cut jewelry is a good option.

Laser cut jewelry business has a huge potential to grow in the market. Especially the young mindset who want to show their individuality through customized apparel. Many factors make laser-cut jewelry a profitable niche to explore.

Now is a time of e-commerce. People can easily list their products on online platforms. An Instagram account, a Facebook page, an online store on Shopify, or simple listings on Etsy and Amazon can make you an entrepreneur.

Why Laser-Cut Jewelry?

Laser-cut jewelry is more practical and economical. It involves many materials, such as wood, acrylic, leather, and metal. The designs are endless and easy to create. Laser cutter for jewelry creates designs that are precise, clean, and versatile. Necklaces, bracelets, earrings, etc. you can create whatever you want.

If you want to know how you can start your own personal jewelry line for the upcoming season, then give a read to the following step-by-step guide:

Step 1: Designing Your Laser-Cut Jewelry

Giving life to your creativity takes much work. That is why it is the foundation step in the making of laser-cut jewelry. There are two methods of creating the designs of laser-cut jewelry:

Using Downloadable Templates:

You can download templates of laser-cut jewelry design files from different websites. Laser-cut files are resolution-free vector files. They contain geometric data in the form of paths or strokes. Each path consists of points. Joining these points can create various shapes or designs.

Creating Your Own Design:

Or you can create one from scratch. No matter how good the laser-cut design you find, it can never compensate for your personal creativity level. The best method is to combine your creative element with several jewelry-making ideas available online. If you are looking for a design source, then look no further and just visit xTool Projects.

When you look at the xTool Project's homepage, you will know why it is the most recommended site for laser-cut files. From free downloadable laser files to a huge variety of DIY ideas, they have everything.

While designing the jewelry, you need to be aware of the current trend. You should know which type of laser-cut jewelry is in demand. Is it laser-cut wood jewelry or laser-cut acrylic jewelry? The best product is the one that incorporates your creative element with the ongoing trend.

Step 2: Selecting Materials

Laser-cut jewelry can be made using different types of metallic and nonmetallic elements. The metallic elements include stainless steel, gold, silver, copper, etc. The nonmetallic elements include acrylic, wood, leather, etc.

Not every machine is compatible with every material. Make sure that the laser cutter you pick is compatible with your jewelry materials. This laser cutting materials guide will help with your choice.

Step 3: Setting Up the Laser Cutter/Engraver

Once you have created the laser cut file and chosen the material for your jewelry, the next step is setting up the laser cutter/engraver.

It would be best if you were careful about setting the right parameters for different materials. xTool provides you with a complete list of their laser cutting machines and the materials and parameters that are compatible with them.

Following the right parameters is important. It is because it is imperative to the creation of perfect finished results.

Step 4: Production Process

Thanks to the latest technology of xTool’s laser cutting machines, that is extremely simple. Just click on the "start" button on your laptop screen and press the button on the machine. The machine will cut and engrave the design on your desired material in the blink of an eye. You will be amazed to see the clean and precise cuts.

Step 5: Post-Creation Processes

The final step involved adding additional components to the finished products. In other words, it involves the assembling process. For example, if you are making laser-cut earrings, then you will add hooks in this step. In case your finished product is a necklace, then you will add chains. As simple as that!

Conclusion

The trend of laser-cut jewelry is reaching new heights. The trends keep changing, and every trend is an opportunity for business minds to capitalize on. Therefore, if you want to start a lucrative laser cut jewelry business, buy a laser cutting machine and give life to your creativity.