How to Use Printable Vinyl (HTV + Vinyl Sticker)

Heat transfer vinyl is one of the popular ways of stylizing and customizing fabrics. The typical approach is taking a colored vinyl sheet, cutting it, and then heat pressing it onto the fabric. This approach, being simple, also limits the design and color choices.

That’s where printable vinyl steps in. You can print any complex design through your regular printer. Then, cut it in the same manner as simple vinyl, and transfer the made design onto fabric using a heat press. There’s still more to the story.

In this article, we will dive into the world of printable vinyl. You’ll learn about its types, how to use it, and the tools you need to create standout custom apparel.

In This Article

- Types of Printable Vinyl

- Tools and Supplies Needed

- Step-By-Step Guide to Using Printable Vinyl

- FAQs of Using Printable Vinyl

Types of Printable Vinyl

Printable vinyl is a PVC-based sheet that behaves as a blank canvas – you can print designs directly onto it, as you would do on regular paper. It’s available in two forms: Printable Heat Transfer Vinyl and Printable Vinyl Stickers.

Printable Heat Transfer Vinyl (HTV)

This vinyl is plain, non-sticky, and requires heat to adhere to fabrics. After printing and cutting your design, you heat press it onto the fabric for a lasting finish.

Printable Vinyl Sticker

This type comes with a sticky back and doesn’t require heat pressing. After the printing-cutting job, you simply peel and stick it onto surfaces.

Considering its similar work nature, it’s often mistaken for sticker paper. But they are not the same. Sticker paper is made of a paper-based material, sometimes with a glossy polypropylene finish, while vinyl sticker is polyvinyl(plastic), with much more durability and water resistance.

Tools and Supplies Needed

Common Materials for Both Types

Printable Vinyl Rolls

Printer compatible with vinyl

Vinyl can be printed using regular inkjet or laser printers, but inkjet printers are generally preferred. Some laser printers generate high temperatures that can distort vinyl due to its low melting point. And for printing, solvent-based inks are recommended as they stick well and are long-lasting.

Vinyl cutter

After printing, vinyl needs to be cut. Simple designs can be cut with scissors, but for detailed and complex edges, a vinyl cutter is a better option for accuracy.

Instead of buying a printer and vinyl cutter, why not switch to a versatile machine, such as xTool M1 Ultra? It’s the world’s first craft machine to have four different working modules – laser cutting, blade cutting (vinyl), inkjet color printing, and pen drawing.

With M1 Ultra, you get a machine that not only solves the vinyl problem but unlocks options for multiple crafting opportunities.

xTool M1 Ultra

Multi-functional Vinyl Cutter

It features blade cutting specialized for vinyl cutting, and laser cutting, painting and drawing for various craft needs.

Learn MoreFor Printable HTV

For printable HTV, you’ll need two additional accessories for the heat transfer process.

Teflon Sheet/Butcher Paper

You can either place butcher paper or Teflon in between the vinyl and heat press surface to avoid burns to the vinyl.

Heat Press or Iron

For sticking printable HTV onto a surface, you need a tool that applies heat and even pressure. An iron is a simple option and works for small designs, but it’s not the best for larger or detailed ones. A dedicated heat press is the better choice for consistent results.

Step-By-Step Guide to Using Printable Vinyl

Once you have the tools in hand, you just need to follow this sequence of steps.

We have tried this procedure for creating a printable HTV design on a white tote bag.

Step 1: Create the Design

To start, you need a design for printing. The easiest and most creative way is using AIMake. This AI tool can transform your ideas into a print-ready image within seconds.

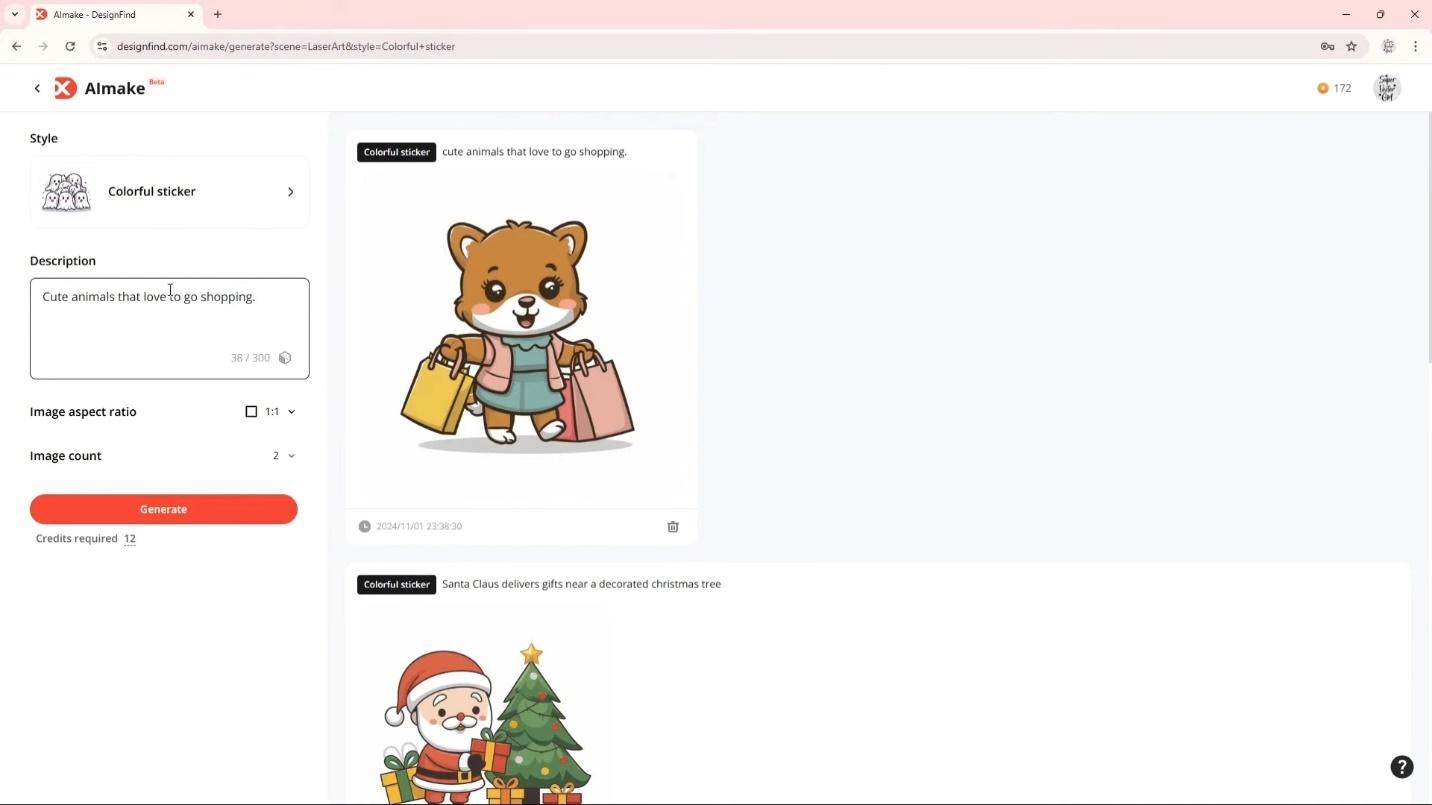

Navigate to AIMake, select a design style of your choice, and click on it. For this project, we chose the ‘colorful sticker’ style.

Add a short text prompt like “cute animals that love shopping,” and click ‘generate.’ Your design will be created instantly and available for free download.

Step 2: Edit and Customize Design in XCS

Import the design file directly into the XCS software from the AIMake interface.

Use the ‘Edit’ menu and the ‘Magic Wand’ tool to remove the background. Resize the design to fit your project.

To prepare for cutting, click the image and use the ‘Outline’ option. Define an offset value. 0.5 would be a suitable outline for a tote bag design.

Step 3: Setup Printing and Cutting Modules

In the XCS, change the processing mode to ‘multi-module processing’. For the outline, you need to select the fine-point blade. Set pressure to 85, speed to 80, and one pass.

For printing, set intensity to 60 and two passes. Position your design on the canvas to match where you’ll place the vinyl, then click ‘preview.

Step 4: Setup the Modules in xTool M1 Ultra

Attach the blue mat to the M1 base, insert the fine-point blade, and the inkjet printing module. Place the printable heat transfer vinyl onto the mat and close the lid.

Step 5: Initiate the Printing and Cutting Process

Press the start button in XCS and on the machine to begin. The inkjet module will first print the design, and the fine-point blade will cut it out precisely.

Step 6: Heat Press the Vinyl with xTool Heat Press

Prepare the fabric by cleaning it with a lint roller and preheating it for 5 seconds. Carefully peel off the vinyl backing and position it on the fabric.

Cover the design with butcher paper, a Teflon sheet, or both. Use the xTool Heat Press to apply firm pressure at 315°F for 30 seconds.

Your design is now successfully transferred onto the tote bag!

FAQs of Using Printable Vinyl

What is printable vinyl?

Printable vinyl is a blank polyvinyl (PVC) sheet designed for printing detailed designs, much like paper. It works with most inkjet or laser printers and can be used for creating custom designs for fabric.

Is printable vinyl the same as sticker paper?

No, they are different. Sticker paper is paper-based and often has a glossy or matte finish, but it lacks durability. Printable vinyl, on the other hand, is a plastic-based material, much more water-resistant and long-lasting.

Do you need to mirror the design for printable vinyl?

No, mirroring is not required for printable vinyl. The design is printed on the top surface and applied directly during heat pressing without reversing the image.

What kind of printer do you need for printable vinyl?

Inkjet or laser printers both can be used for printable vinyl. However, inkjet printers are preferred for more vibrant and detailed results, especially for photographic images. Also, the high temperature inside the laser printer may not be suitable for vinyl.

Can you use sublimation ink on printable vinyl?

If the question is whether sublimation ink can be used to print directly on printable vinyl using a sublimation printer, the answer is no. However, it is possible to sublimate a design onto certain types of vinyl.

Is printable vinyl waterproof?

The vinyl itself is waterproof, but the ink used for printing might not be. For durability, use solvent-based or waterproof inks.

Is printable vinyl permanent?

Yes, printable vinyl is permanent once applied properly. It adheres to the surface for long-term use.

Can you use printable vinyl on shirts?

Yes, printable vinyl works similarly to plain heat transfer vinyl (HTV) and can be used on shirts for vibrant and detailed designs.

Related Reading: