Is Air Assist For A Laser Engraver Worth It?

For those familiar with a laser cutter, the term ‘air assist’ might not be new. While some machines come equipped with this feature, others offer it as an optional add-on. But is air assist truly a game-changer? Is it worth investing in if your machine doesn't already have it?

In this article, we will get into the basics of air assist and how it benefits the laser cutting and engraving operation. At the end, we’ll also share some tips to effectively use the air assist system.

In This Article

- What Is Air Assist On A Laser Engraver?

- What Does Air Assist Do For A Laser Engraver?

- Tips For Using Air Assist On A Laser Engraver

- Conclusion

What Is Air Assist On A Laser Engraver?

During laser operations, material is burned off to cut or engrave. Consequently, a significant amount of smoke, fumes, and material particles are produced. To get rid of these particles, the air assist system comes into play.

Air assist is a focused stream of compressed air directed right over the portion being processed by the laser. Imagine it as a concentrated air beam, which swiftly clears away unwanted particles, ensuring a cleaner and more efficient laser operation.

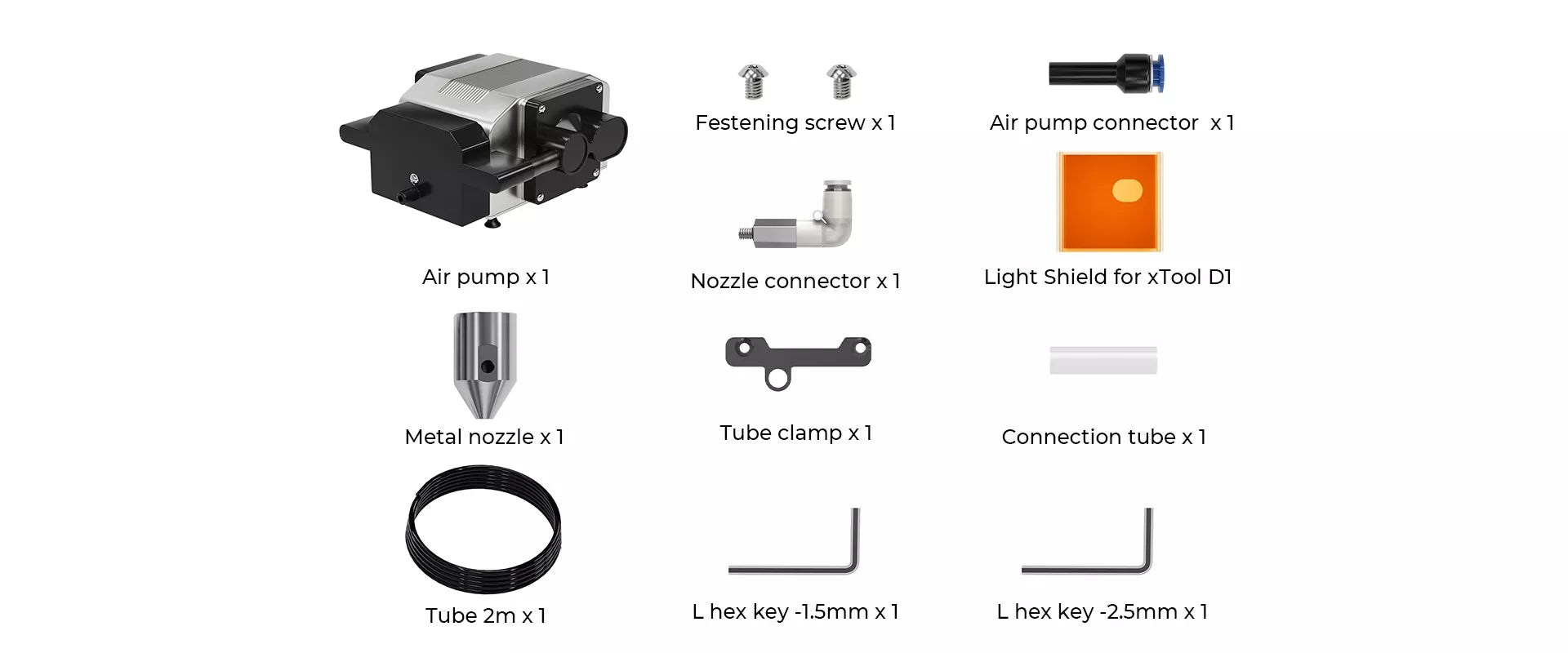

The air assist for laser engraver primarily consists of two main components:

Compressor: Located outside of the laser compartment, the compressor is the powerhouse that supplies cool compressed air. Some compressors have a knob that allows users to adjust and configure the flow of the compressed air. This is particularly useful when you need to reduce flow when engraving and cutting thin materials.

Nozzle: It is mounted directly in front of the laser module. The nozzle’s role is to channel the compressed air from the compressor directly onto the material being engraved or cut. It keeps the laser module cool and moves away debris and fumes promptly from the work area.

What Does Air Assist Do For A Laser Engraver?

Laser engraving technology provides a rapid and precise method to cut materials, but it comes with inherent challenges. The laser engraver air assist addresses these issues:

1. Improved Quality

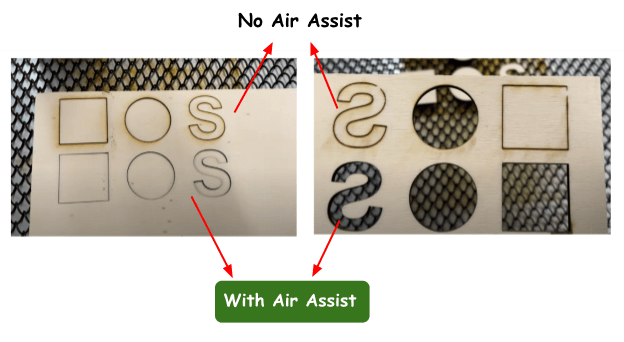

During laser cutting, the material undergoes burning to achieve engraving or cutting. This action can leave behind unwanted deposits on the surface, which affects the final appearance. The air assist laser cutting technique blows away these particles as they form. This results in fine, smooth, and quality cuts.

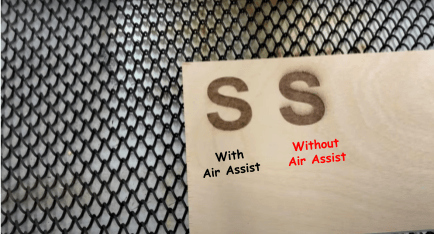

2. Reduce Charring

Laser operations on wood often result in burnt marks around the cut. This blackened, partially burnt region is termed ‘char’. However, when a stream of compressed is thrown along with the laser, it prevents the laser from burning those adjacent areas, reducing charring.

Related reading:

How to avoid burn marks when laser engraving wood

3. Safeguards the Laser Lens

The air assist mechanism efficiently clears away the smoke and debris produced during the laser’s operation. This action keeps the laser head lens free from contaminants and enhances its longevity.

4. Pristine Finish

The compressed air rapidly cools the surface being cut, preventing any warping or color changes caused by excessive heat. This ensures the end product has crisp lines, detailed patterns, and a flawless surface.

Test Results with xTool Air Assist Set

The advantages of the air assist for laser cutting aren’t just theoretical; they’re backed by tangible results. Our users have conducted several tests with the use of the xTool D1 Pro air assist set:

1/4 Inch Plywood Cutting Test:

One of the xTool users performed a test with and without the air assist set on D1 Pro; significant improvements were observed. Without air assist, the laser couldn’t cut entirely through the material. But with the air assist module, using identical power and speed settings, the laser achieved a full cut.

1/2-inch Plywood Engraving Test:

Another test was conducted on ½ inch plywood. This time the wood was engraved. Engravings with the air assist had less soot and overburn.

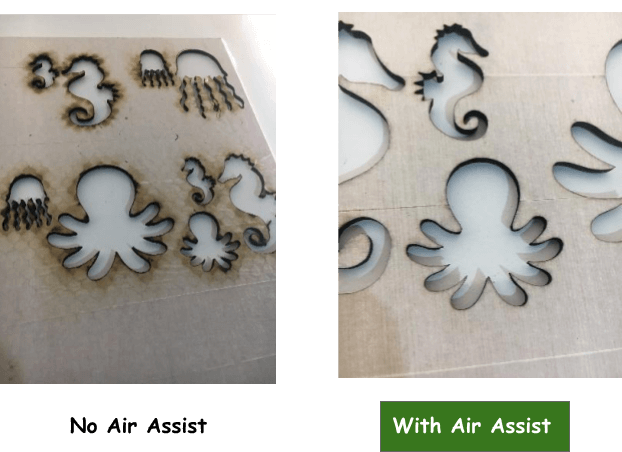

Wooden Project Cut Outs / Churring Effect:

Another community member tested out the air assist for wooden cutouts. The results were drastic. It was observed that the pattern on the wood after cutouts was much cleaner without burning marks.

Tips For Using Air Assist On A Laser Engraver

In the laser engraving world, precision and clarity are supreme. The air assist system has emerged as a valuable ally in achieving these goals, addressing many challenges that engravers often face.

To truly harness the potential of this tool, consider the following tips:

1. The Nozzle Shouldn’t be Close to the Material

Placing the nozzle too close to the nozzle results in blurry and uneven results. You need to place it at an optimum distance. We recommend that the nozzle should be at least 2 mm away from the material. This not only makes it effective but also prevents any debris from clogging the tip.

2. Not All Materials Are Suitable For Air Assist

Air Assist is usually recommended for thick materials or materials that may burn out during operation (such as wood). For lighter metals, the air assist might be counterproductive as it yields blurred patterns.

3. You Don’t Have to Increase Pass Times with Air Assist

People think they need to increase pass times when using air assist to get more clear results. However, both aren’t related. In fact, multiple turns can burn out the material, negatively impacting the quality. So, if you want to improve clarity, the tweaks need to be done on focal length or power.

4. Add Aluminum Heat sink to Air Assist Compressor

Air assist may be an optional accessory but it is vital for laser diodes which need to stay cool to perform well. The compressor of this system may get hot when used for a long period.

To cool down the air compressor, you can attach Aluminium heatsinks to its body. These heatsinks come with double-sided adhesive tape, so pasting them is an easy task. More fins means more heat exchange with the surroundings. This keeps the compressor cool and ultimately, the laser cutter receives cold air.

Aluminum HeatSink Attached to Air Assist Set

5. Nozzles Aren’t Recommended for Engraving

We don’t recommend a nozzle for the engraving process because airflow can alter the engravings. However, if you want to use it, we advise using it via a machine that allows for change in airflow. For instance, xTool D1 Pro Assist has a knob, which can be used to lower airflow for engraving operations.

Conclusion

The air assist system, whether built-in or an add-on, undeniably elevates the quality of cutting and engravings. It addresses the common challenges of material deposits, charring, and lens contamination.

Our multiple cutting tests reveal how good it can be for laser operation. In short, an air assist is worth it for a laser as it adds more clarity and quality to the final results.