Introducing Air Assist Set for xTool M1

Posted by WINNIE LI

xTool M1 is a hybrid laser and blade cutting machine perfect for making customized items and gifts. The machine is a combination of advanced and exceptional features, such as a built-in camera, batch processing, auto-focus, and extra precise cutting and engraving. However, it didn’t have an air assist set to deal with the smoke and debris accumulated in the working area.

xTool is proudly announcing a special Air Assist set that is custom-made for xTool M1. It is made by considering the requirements and constraints of the machine and can offer excellent cutting and engraving results. In this article, we will discuss air assist and why it is necessary. We will introduce xTool M1’s Air Assist set and the advantages it offers.

What is an Air Assist on a Laser Engraver & Cutter?

An Air Assist is a necessary part of a laser engraving and cutting machine. As the name suggests, it assists the engraving and cutting processes by blowing air at very high pressure. It can be turned on or off when needed.

It consists of a nozzle, air pump, tube, and some other small parts. The nozzle is attached to the laser module. The air comes out of the nozzle in the direction of the laser beam and keeps the smoke and debris away from the engraving & cutting area.

The air assist is powered by an air pump or compressor. It compresses the air and pumps it to the nozzle through the tube. The nozzle is located just near the laser module and works simultaneously with the laser.

The pressure and flow rate of the air assist are immensely high due to the air compression. Thus, the air coming out of the nozzle is sufficient and powerful enough to blow the particles and smoke.

Why Use an Air Assist When Laser Engraving & Cutting?

In DIY and small laser engraving and cutting machines, the Air Assist comes as an accessory. Therefore, you need to purchase it separately and then attach it to the machine. Thus, many users ask whether it is necessary to use an assist or not and why they should use it.

An air assist has many benefits, and there are various reasons to use it in your laser engraving and cutting machine.

Laser beams are very powerful; they can easily and quickly increase the temperature of the object. Therefore, when the laser cuts or engraves the object, due to high temperature, excessive heat and smoke is produced. Moreover, there are debris and particles that result due to cutting and engraving.

If you do not use the air assist, there are higher chances of a fire. The debris can catch fire in no time, and the fire can spread quickly. But due to the powerful blow of air assist, the debris is moved away from the cutting and engraving area. Thus, it is quite helpful in reducing fire risk. Plus, the object is clean enough to be used directly without the need for extra cleaning.

The smoke that is produced during the process also creates many issues. Firstly, it leaves burn marks on the edges of the object, especially wood. The color of the wood also turns yellow as the temperature of the smoke is quite high. Secondly, it reduces the overall power of the laser by coming in between the laser and the object. Thus, it prevents deeper cuts and disturbs the laser beams.

Using an air assist, you can blow the smoke away. It will ensure a cleaner surface and no discoloration. The quality of the result is improved as well as the efficiency of the machine. Moreover, it increases the life of the laser module.

Advantages of xTool M1 Air Assist

xTool’s tailor-made air assist for M1 is exceptional. It offers various advantages that will compel you to have it and enjoy better results using your M1. Let’s have a detailed look at the advantages it offers.

a. Cleaner Cutting Surface & Smooth Cutting Edge

The powerful airflow of the M1 air assist is incredible. It blows the particles and the smoke away from the engraving and cutting area and keeps the area as clean as possible. It prevents the accumulation of high-temperature smoke that results in discoloration and burn marks.

The burn marks are due to the particles of the smoke that stick to the edges. With the help of M1 air assist, you can get rid of this issue. The edges are quite clean and smooth.

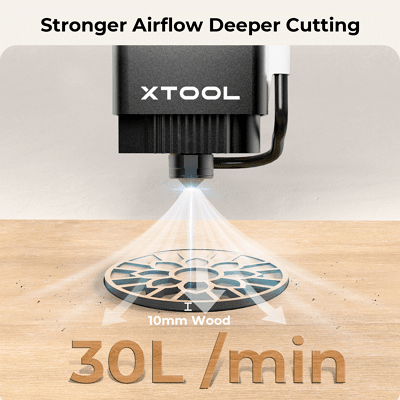

b. Strong Airflow Enables Deeper Cutting

The air assist offers an immensely powerful airflow of 30L/min. It removes the residue and smoke from the area to make it clear for the laser. Therefore, the laser can work efficiently and offer deeper cutting.

c. Extend the Lifetime of Laser Lens

The lens of the laser module has greatly affected the accumulation of debris and smoke particles. It reduces the performance, efficiency, and life of the laser module. xTool’s Air Assist for M1 avoids the accumulation of residue and keeps the laser lens cleaner.

d. Elegant Design, Easy to Use with Magnetic Attachment

The design of the air assist is one-of-a-kind. The air pump is compact and elegant. Plus, the arrangement of the pump and tubes is more than perfect; it is along the walls of the machine, and everything looks tidy and properly arranged.

The magnetic air nozzle is exceptional. You can easily attach or detach it from the module whenever needed.

e. Designed for Household Use with Low Working Noise

The noise of the air assist is minimal. You can easily use it inside your home or garage. It won’t disturb others. It is ideally designed for household use.

f. Work in Combination with M1 Honeycomb Panel

The air assist can work along with the M1 Honeycomb panel. The panel makes the exhaustion process faster and prevents the accumulation of smoke. It protects the back of the object as well as your working table/desk.

Final Words

An air assist is necessary for your laser cutting and engraving machine to improve efficiency and lifespan and deal with the accumulated debris and smoke. Now, xTool M1 also has a tailor-made air assist set that can improve the performance of the machine and offer exceptional results. You can upgrade your M1 and connect the latest air assist to uncover the full potential of the machine. It is available in the store, so grab your air assist set and enhance your product range.

For more questions, please join our Facebook group to get inspired

SHARE: